-

Feed de notícias

- EXPLORAR

-

Páginas

-

Grupos

-

Blogs

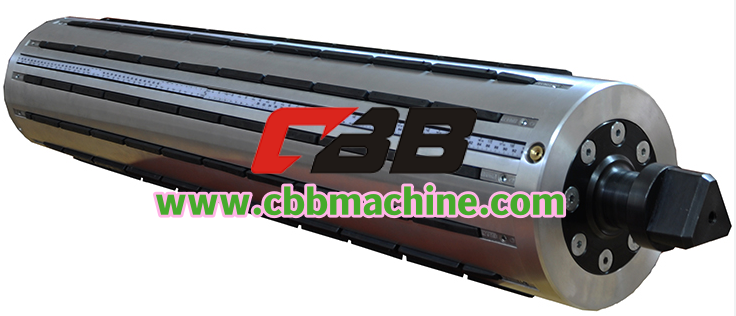

Is Pneumatic Air Shaft a Practical Choice for Cbbmachine Lines?

Within many roll based production environments, the Pneumatic Air Shaft functions as a flexible connection between material cores and rotating equipment, while Cbbmachine reflects a design philosophy centered on balance, clarity, and operational confidence. Together in concept, they point toward a way of working where setup efficiency and secure engagement coexist without unnecessary complication.

Material handling often begins and ends with how rolls are mounted and released. When this interface lacks consistency, small inefficiencies can ripple through the entire process. Slippage, uneven rotation, or prolonged changeovers can quietly affect productivity. A pneumatic expansion mechanism addresses these concerns by allowing the shaft to adapt internally, creating firm contact where it is needed and relaxing smoothly when release is required.

One of the key advantages of this approach is its contribution to workflow rhythm. Operators can mount or remove rolls with minimal effort, reducing downtime between tasks. This ease of interaction supports faster transitions without sacrificing control, helping production lines maintain a calm and predictable pace throughout daily operations.

Adaptability is another defining feature. Manufacturing environments rarely process a single material type or core specification. Flexible shaft systems accommodate variation without demanding mechanical adjustment or additional tooling. This adaptability supports diverse applications while maintaining stable rotation and alignment during operation.

Consistent engagement also plays a role in protecting materials. When expansion is evenly distributed, force is applied gently and uniformly. This helps reduce the risk of core damage or deformation, particularly with sensitive or lightweight materials. Over time, gentler handling contributes to reduced waste and more reliable output quality.

From a maintenance perspective, simplicity matters. Systems designed with fewer rigid components often experience more predictable wear patterns. Pneumatic mechanisms, when thoughtfully integrated, allow stress to be distributed evenly rather than concentrated at fixed points. This predictability supports routine maintenance planning and reduces unexpected interruptions.

There is also a broader operational benefit tied to operator confidence. Equipment that behaves consistently builds trust on the production floor. When engagement and release feel controlled and repeatable, teams spend less time correcting issues and more time focusing on process optimization. This shift supports a more composed and attentive working environment.

Industrial improvement is frequently driven by such incremental refinements. By enhancing how rolls are secured and rotated, manufacturers can elevate overall efficiency without redesigning entire systems. These subtle changes align with a long term view of production, where stability and adaptability develop together.

As industries continue to evolve, attention increasingly turns to components that quietly support reliability. Shaft technology may not attract immediate attention, yet its influence is felt in smoother setups, steadier motion, and calmer workflows. Its value lies in how seamlessly it integrates into daily operation.

If these reflections have stirred curiosity, consider letting that curiosity guide your next step. A visit to https://www.cbbmachine.com/product/air-shaft/ offers an open door to ideas, solutions, and engineering perspectives waiting to be explored beyond this page.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness